Rubber Cords Manufacturer in India

Introduction

Established in the year 2018, at Faridabad (Haryana, India), we, MILAN RUBBER, are known as the most prominent manufacturers, exporters, and suppliers of a comprehensive assortment of Rubber Pipe, Rubber Cord, Tube, and Rubber Products such as EPDM, UPVC Section Rubber, and more. Our product range includes Glass Rubber Beadings, Industrial Rubber Beadings, and Rubber Beadings, all fabricated using premium quality raw materials and advanced technology, in accordance with international standards.We are the best EPDM Rubber Cord Supplier in USA.

In the complex machinery of contemporary industry, from the buzzing engines of cars to the exact motions of production tools, a myriad of parts collaborate in concert to guarantee smooth functioning. Among these, rubber cords are often overlooked but undeniably vital. These strands of elastomeric material, which appear simple, are actually the unsung heroes that provide sealing, cushioning, insulation, and durability across a wide range of applications. We are the best Rubber Cords Supplier.

Milan Rubber, a prominent manufacturer of rubber cords in India, has spent decades honing the craft and understanding of rubber cord manufacturing, fully grasping its vital importance.This piece investigates the realm of rubber cords in detail, examining their various kinds, complex production methods, numerous uses in Indian industries, and the reasons that a premium rubber cord is essential. Milan Rubber’s dedication to quality, innovation, and customer satisfaction will be highlighted, reinforcing their status as a top choice in the Indian market.

What Exactly are Rubber Cords

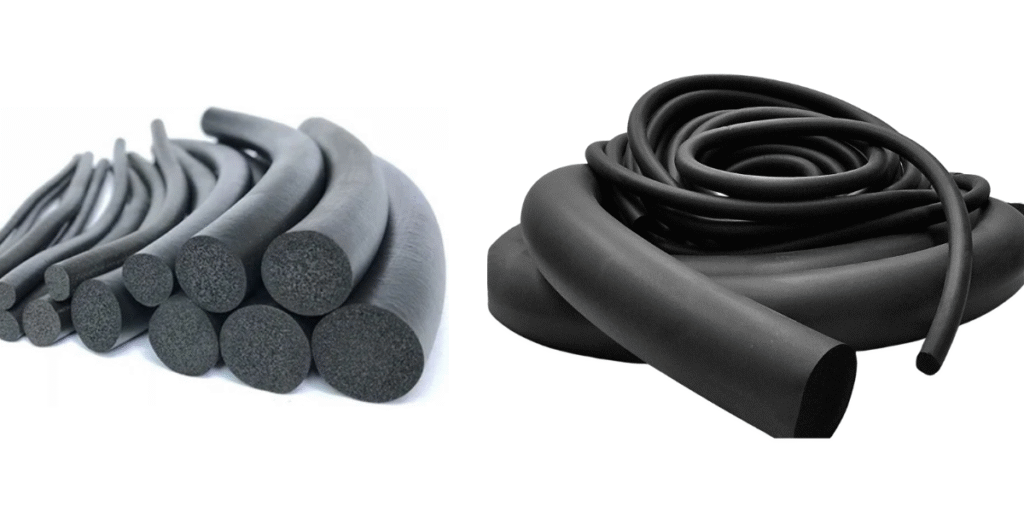

Rubber cords essentially consist of extruded profiles manufactured from different rubber compounds. They feature a continuous cross-section that can be round, square, rectangular, or even custom-designed, providing exceptional flexibility in both design and application, unlike molded parts. They often serve the main purposes of creating effective seals, preventing liquid or gas leaks, dampening vibrations, and providing insulation.Rubber cords are versatile due to the natural qualities of rubber: its elasticity, resilience, and capacity for compounding with additives to produce desired traits. This enables manufacturers to customize cords for highly specialized settings, including extreme temperatures, corrosive substances, or intense mechanical stress. Wea re the best Rubber Cords Exporter.

Why Choose Milan Rubber

- Steadfast Quality Commitment: At Milan Rubber, quality goes beyond mere jargon; it is the foundation of what we do. From sourcing high-quality raw materials to conducting final inspections of our products, we follow strict international quality standards at every step of the manufacturing process. Our products are well-known for being environmentally friendly, having excellent tensile strength, featuring a fine finish, and resisting moisture and water. Thanks to this commitment, every rubber cord that departs from our facility is guaranteed to perform outstandingly and be long-lasting.

- Vast Produktportfolio und Individualisierung: Wir sind uns bewusst, dass jede Branche und Anwendung spezifische Anforderungen aufweist. Milan Rubber provides a wide range of rubber cords, such as EPDM, Nitrile, Silicone, and Neoprene, each designed for specific characteristics like resistance to oil, chemicals, temperature variations, and ozone. Outside of our standard offerings, we are exceptional at delivering tailored solutions. Our skilled team collaborates closely with clients to create customized rubber cords that precisely meet their specifications for size, shape, hardness, and material composition.

- Advanced Manufacturing Infrastructure: Our cutting-edge manufacturing plant located in Thane, Maharashtra, features modern equipment and advanced extrusion technology. This enables us to manufacture rubber cords of high precision that have a uniform quality and efficiency, satisfying the requirements of both extensive industrial operations and tailored custom requests.

- Experienced and Committed Team: Milan Rubber’s core asset is its workforce, which is both skilled and seasoned. Our team of experts, including engineers, quality supervisors, and production and sales personnel, has extensive industry knowledge and is dedicated to achieving excellence. With the visionary leadership of our we have developed a culture focused on ongoing enhancement and customer orientation.

- Client-Centric Approach: Our priority is to comprehend the needs and challenges faced by our clients. We have gained the trust and confidence of a broad customer base in the domestic market, and increasingly on an international scale, due to our transparent and ethical business practices and commitment to punctual delivery. Our belief lies in establishing lasting collaborations through the provision of dependable products and outstanding service.

- Competitive Pricing: Although we always maintain high quality, Milan Rubber is dedicated to providing prices that are competitive. We are able to offer solutions that are economical yet do not compromise on performance or durability, thanks to our effective manufacturing processes and careful sourcing strategies.

- Sustainability Focus: Milan Rubber is aware of its impact on the environment. We are always working to enhance our production processes in order to cut down waste and lessen our effect on the environment. Our long-lasting products, thanks to their longevity, help promote sustainability by lessening the frequency of necessary replacements.

Applications of Rubber Cords

- Automotive Sector: Rubber cords play a crucial role in the performance and comfort of vehicles, from door and window seals, O-rings, and gaskets to vibration dampeners and protective sleeves for wiring harnesses. They guarantee that air and water do not penetrate, lower noise levels, and safeguard delicate parts.

- Construction and Infrastructure: Rubber cords serve as sealing components in windows, doors, and curtain walls, offering protection against the elements and thermal insulation. They are also utilized in expansion joints, anti-vibration mounts for machinery, and serve as protective bumpers and edge protectors.

- Electronics and Electrical: Rubber cords are essential for safeguarding electrical wiring, offering seals in electronic enclosures to block dust and moisture entry, and serving as strain relief components, all thanks to their outstanding insulating properties. In high-temperature electrical applications, silicone cords are particularly preferred.

- Food and Beverage Industry: In the food processing, packaging, and beverage dispensing sectors, silicone rubber cords that meet food-grade standards are essential for sealing machinery. Thanks to their odorless, non-toxic, and high-temperature resistant properties, hygiene and safety are guaranteed.

- Medical and Pharmaceutical: Biocompatible silicone rubber cords are utilized for sealing, fluid transfer, and as parts in various instruments in medical devices, laboratory equipment, and pharmaceutical processing.

- Industrial Machinery and Equipment: Rubber cords function as seals in pumps, valves, and hydraulic systems, preventing leaks and offering cushioning and vibration isolation for moving components, ranging from heavy machinery to precision instruments. In certain applications, they also serve as drive belts.

- Marine and Offshore: Rubber cords are utilized in shipbuilding for sealing hatches, doors, and windows, as well as for fendering systems to safeguard vessels and docks from collisions, owing to their durability against water, salt, and severe weather.

- Appliance Manufacturing: Rubber cords are utilized in household appliances such as washing machines, refrigerators, and coffee makers for sealing doors, preventing leaks, and minimizing vibrations.

- Aerospace and Defense: Rubber cords with high performance, particularly those crafted from Viton, are essential for aerospace applications due to their ability to withstand extreme temperatures, fuels, and hydraulic fluids, thereby guaranteeing dependable function in crucial systems.

Table of Specifications Rubber Cords

| Parameter | Specification |

|---|---|

| Material Grades | Rubber Cords |

| Hardness Range | 40 Shore A to 90 Shore A |

| Temperature Range | -60°C to +300°C (depending on material) |

| Cord Diameter | 2 mm to 50 mm |

| Tolerance | ±0.2 mm to ±0.5 mm (as per DIN standards) |

| Color Options | Black, White, Red, Blue, Transparent, Custom Colors |

| Length Supply | Continuous coils (up to 100 meters) or cut lengths as required |

| Cross-Section Type | Round (solid and hollow), Square, Rectangular, Custom Profiles |

| Food Grade Options | Available in Silicone and EPDM |

| Oil Resistance | NBR, Neoprene, Viton |

| UV & Ozone Resistance | EPDM, Silicone, Viton |

| Chemical Resistance | Viton, Hypalon, Silicone |

| Compliance Standards | FDA, REACH, ROHS, IS, ASTM, ISO |

Types of Rubber Cords

1. EPDM Rubber Cords

- Features: Excellent weather, ozone, and water resistance

- Applications: Used in outdoor sealing, window glazing, roofing, and automotive industries

2. Nitrile (NBR) Rubber Cords

- Features: Good resistance to oils, fuels, and chemicals

- Applications: Widely used in fuel systems, automotive, and machinery applications

3. Silicone Rubber Cords

- Features: High-temperature resistance and excellent flexibility

- Applications: Ideal for food processing, pharmaceuticals, medical devices, and electrical insulation

4. Neoprene (CR) Rubber Cords

- Features: Good resistance to oils, chemicals, ozone, and weathering

- Applications: Used in HVAC, refrigeration, automotive, and marine industries

5. Viton (FKM) Rubber Cords

- Features: Exceptional heat and chemical resistance

- Applications: Preferred in aerospace, automotive, and high-performance applications

6. Natural Rubber Cords

- Features: Superior elasticity and abrasion resistance

- Applications: General-purpose industrial applications, shock absorbers, and vibration dampers

Conclusion

Though rubber cords are small, they are essential parts that support the functionality and safety of numerous applications in various industries. Having started out small, the Indian rubber cords manufacturing sector has developed into a vigorous and energetic industry that can satisfy the intricate requirements of a contemporary economy. We are the best Best Rubber Cords Manufacturer.

Milan Rubber is a prime example of these very qualities. Their commitment to excellence in manufacturing, combined with their vast experience and wide array of products, positions them as a key player in the Indian rubber cords market. As sectors progress and fresh difficulties arise, businesses such as Milan Rubber will persist as the unacknowledged champions, quietly driving advancement with their essential and adaptable rubber solutions. India’s future in rubber cord manufacturing involves more than just increased production; it’s about creating products that are greener and smarter, with an unyielding commitment to the quality that signifies reliability.