Silicone Tubes Supplier in India

Introduction

Established in the year 2018, at Faridabad (Haryana, India), we, MILAN RUBBER, are known as the most prominent manufacturers, exporters, and suppliers of a comprehensive assortment of Rubber Pipe, Rubber Cord, Tube, and Rubber Products such as EPDM, UPVC Section Rubber, and more. Our product range includes Glass Rubber Beadings, Industrial Rubber Beadings, and Rubber Beadings, all fabricated using premium quality raw materials and advanced technology, in accordance with international standards.We are the best EPDM Rubber Cord Supplier in USA.

In the complex machinery of contemporary industries, ranging from life-saving medical apparatus to high-performance automotive systems, a silicone tube—a component that appears simple—serves a crucial function. These adaptable tubes, celebrated for their remarkable characteristics, have emerged as the preferred choice for numerous fluid transfer, insulation, and protective purposes. For companies in India looking for a trustworthy and top-notch supplier of silicone tubes, it is crucial to comprehend the benefits of this material and the expertise of top manufacturers. This article explores the realm of silicone tubing and underscores the reasons that Milan Rubber distinguishes itself as a leading supplier in India. We are the best Silicone Tubes Manufacturer.

Understanding the Silicone Tubes

High-quality silicone rubber compounds are used to create silicone tubes, which are flexible and resemble rubber tubing. These tubes are renowned for their outstanding heat resistance, non-toxic properties, and high elasticity. They find extensive application in industries that demand hygienic, temperature-stable, and chemical-resistant tubing solutions. Due to their ability to endure extreme temperatures from -60°C to 250°C, silicone tubes are appropriate for environments with both low and high temperatures. In addition, due to their non-toxic and non-reactive characteristics, they are well-suited for use in food-grade, medical, and pharmaceutical applications. We are the best Silicone Tubes Exporter.

Why Choose Milan Rubber

- Uncompromising Quality Control: The foundation of Milan Rubber is quality. We recognize that for crucial applications, compromises are not acceptable. Our silicone tubes are made from 100% pure silicone rubber and comply with international quality standards, including US FDA 21 CFR 177.2600 and USP Class VI regulations for medical and food-grade applications. This careful method guarantees that our products are flawless, have outstanding abrasion resistance, and show exact dimensional precision.

- Extensive Selection and Customization: Our product line includes a wide variety of silicone tubes, offered in different specifications, dimensions (ranging from micro to large diameters), and grades. Milan Rubber offers a solution whether you need general-purpose tubes for industrial applications, platinum-cured tubes for medical and pharmaceutical purposes, or specialized tubes for high-pressure systems. Additionally, we distinguish ourselves through our capability to deliver personalized solutions that are designed specifically for your needs. We collaborate closely with clients to grasp their specific needs and provide products that seamlessly integrate with their systems.

- Advanced Manufacturing Processes: Our cutting-edge manufacturing facility utilizes advanced methods, such as extrusion processes, to create seamless and consistent silicone tubes. We make certain that our materials are processed in a way that boosts essential characteristics, while keeping the natural benefits of silicone rubber intact, including its high elongation and tear strength. This careful production process ensures a constant quality level and ideal performance.

- Prompt Delivery and Streamlined Logistics: We recognize that prompt delivery is essential for smooth operations. We guarantee the timely delivery of your orders throughout India, including key cities such as Bangalore, Mumbai, Chennai, Hyderabad, Delhi, Ahmedabad, Pune, and Kolkata. This is made possible by our efficient production process as well as our warehousing and logistics systems.

- Client-Focused Approach and Open Practices: At Milan Rubber, the top priority is to satisfy the customer. We are of the opinion that lasting relationships founded on trust and transparency are important. From the first consultation to after-sales service, our team of specialists offers dedicated support, guaranteeing a seamless and worry-free experience. We further strengthen our status as a favored partner through our ethical business practices and competitive pricing.

- Comprehensive Product Selection: Milan Rubber provides a wide selection of silicone tubes designed to meet the demands of different industries. This comprises transparent silicone tubing, colored variants, and specialized types such as platinum-cured silicone tubing for essential applications.

Applications of Silicone Tubes

- Medical and Pharmaceutical: Silicone tubing is essential in this sector. Medical-grade silicone tubes (often platinum-cured and compliant with USP Class VI standards) are essential for applications such as peristaltic pump tubing in drug delivery systems, IV fluid lines, catheters, surgical drains, and laboratory equipment due to their biocompatibility, non-toxicity, and sterilizability.

- Food and Beverage: Silicone tubes that meet food-grade standards and comply with FDA 21 CFR 177.2600 regulations are commonly utilized in food processing, dairy, brewing, and bottling facilities for the transport of liquids, slurries, and powders. Thanks to their non-stick characteristics, ability to withstand heat, and simple cleaning process, they are perfect for ensuring cleanliness and avoiding product contamination.

- Automotive: Silicone tubes find a range of applications in the automotive industry, such as coolant hoses, vacuum lines, turbocharger hoses, and wire insulation, due to their capacity to endure extreme temperatures, vibrations, and contact with oils and chemicals.

- Industrial and Manufacturing: Silicone tubes provide dependable performance in challenging industrial settings, serving applications ranging from general fluid transfer and pneumatic lines to electrical sleeving, furnace door seals, and chemical processing. Because they withstand heat, chemicals, and abrasion better than traditional rubber or plastic hoses, they are the preferred choice.

- Electronics: Silicone tubes are used for insulation, protection, and wire harnessing in electronic components because of their outstanding electrical insulation properties and resistance to high temperatures.

- Aerospace: The industry’s high-performance requirements demand materials capable of enduring extreme temperatures, pressures, and corrosive conditions. In various systems of aircraft, silicone tubes are used for fluid transfer and as insulation.

Table of Specifications Silicone Tubes

| Specification | Details |

|---|---|

| Material | Silicone Rubber |

| Available Sizes | 0.5 mm to 100 mm inner diameter |

| Wall Thickness | 0.5 mm to 10 mm |

| Temperature Range | -50°C to +250°C |

| Color Options | Transparent, Translucent, Red, Blue, Custom Colors |

| Length Options | Up to 50 meters (customizable) |

| Grade Options | Food Grade, Medical Grade, Industrial Grade |

| Hardness Range | 40 to 80 Shore A |

| Compliance | FDA, ISO 9001:2015, REACH, ROHS |

Advantages of Silicone Tubes

- Outstanding Temperature Resistance: Silicone tubes are renowned for their capacity to endure extreme temperatures, whether high or low. They retain their flexibility and functionality in environments from about -60°C to +250°C, which makes them perfect for applications where thermal stability is crucial.

- Chemical Inertness and Biocompatibility: Silicone is mostly inert, which means it does not react with most chemicals, acids, or solvents. This renders it the preferred option for transferring sensitive fluids, gases, and even pharmaceutical compounds. Moreover, due to its biocompatibility, non-toxicity, and lack of odor, medical-grade silicone is safe for direct contact with human tissues and fluids. This has led to its extensive use in healthcare applications.

- Flexibility and Durability: Silicone tubes, though robust, exhibit remarkable flexibility, facilitating easy routing and installation within intricate systems. They do not kink, compress, or lose their shape after being bent or stretched multiple times. Due to this intrinsic durability, the service life is extended and the necessity for regular replacements is diminished.

- Resistance to Environmental Factors: Silicone shows remarkable resistance against UV radiation, ozone, moisture, and harsh weather conditions. This renders them appropriate for outdoor use and in settings where contact with severe weather is a worry.

- Sterilizability and Hygiene: Silicone tubes revolutionize sectors that demand extreme cleanliness, like the medical and food processing industries. They can be cleaned and sterilized easily (through autoclaving or other techniques) and resist bacterial growth, ensuring optimal hygiene and the integrity of the product.

- Electrical Insulation Properties: With its high dielectric strength, silicone serves as an outstanding electrical insulator, safeguarding delicate wires and components from heat, moisture, and electrical interference.

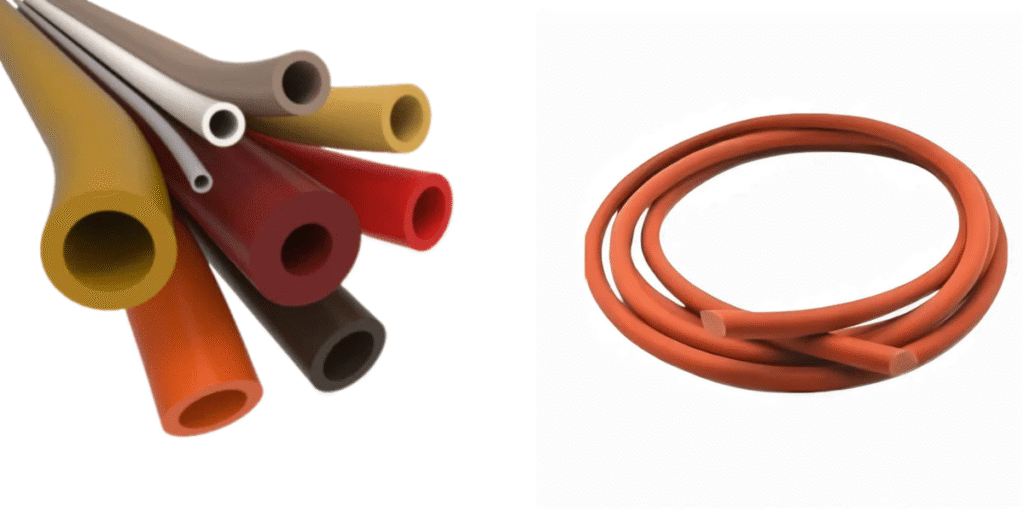

Types of Silicone Tubes

Transparent Silicone Tubes

- These clear, non-toxic tubes are widely used in the food, pharmaceutical, and beverage industries. Their transparency allows easy visual inspection of fluids passing through.

Features:

- Excellent temperature tolerance

- Food-grade certified

- Flexible and lightweight

Coloured Silicone Tubes

- Available in a variety of colours like red, blue, green, and white, these tubes help in color-coding different fluid systems in industries.

Features:

- Customizable colours

- High thermal stability

- Resistant to chemicals and weathering

Platinum-Cured Silicone Tubes

- Specially designed for pharmaceutical and medical applications, these tubes are manufactured using platinum curing, ensuring biocompatibility and minimal extractables.

Features:

- Ultra-pure and FDA-approved

- Odourless and tasteless

- Highly durable and transparent

Braided Silicone Tubes

- Reinforced with polyester or fibreglass braiding, these tubes offer enhanced pressure resistance and are ideal for high-pressure fluid transfer applications.

Features:

- Pressure and kink-resistant

- Durable and long-lasting

- Suitable for industrial and chemical processes

High-Temperature Silicone Tubes

- Manufactured for extreme conditions, these tubes can endure high heat up to +250°C, making them perfect for applications involving hot fluids and gases.

Features:

- Exceptional heat resistance

- Flame retardant options available

- Chemically inert and non-reactive

Conclusion

With the ongoing innovation and growth of industries in India, the need for high-performance materials such as silicone tubes will increase. Their unparalleled characteristics regarding temperature resistance, chemical inertness, flexibility, and hygiene render them essential in a variety of applications. We are the best Best Silicone Tubes Supplier.

If you are in search of a trustworthy supplier of silicone tubes in India, Milan Rubber is the answer. Our dedication to providing high-quality products, tailored solutions, technical know-how, and a customer-first philosophy positions us as your ideal partner for all silicone tubing requirements. Select Milan Rubber, and discover how commitment and quality can transform your industrial processes.